Floor Trusses

Floor trusses are the solution to many floor framing problems. Architects, engineers and contractors are using floor trusses to create high quality, squeak-free construction with the added benefits of reduced framing time, waste, and callbacks. Design versatility and the open space provided between the chords and webs of floor trusses for mechanical and plumbing runs offer tremendous advantages for today’s complex and sophisticated building designs.

Benefits of a Floor Truss

- Floor trusses are built with 2x4s or 2x3s with a wide, stable bearing surface that is easier to work on and around.

- The wide nailing surface provides for easy gluing and quick, accurate attachment of sheathing, reducing squeaks and improving floor performance for the life of the structure.

- The spacing of floor trusses allows for maximum structural efficiency and speed of installation.

- Stiffness and strength can be designed into the floor truss, creating a more solid floor.

- Special bearing, cantilever and balcony details are easily built in.

- Shrinkage, warping or twisting are minimized.

- Long spans and girder truss options reduce the need for intermediate bearing walls, beams, columns and footings – saving time and construction costs.

- The open web configuration leaves plenty of room for plumbing, electrical and mechanical runs.

- Floor trusses provide opportunity for shallower or deeper depths.

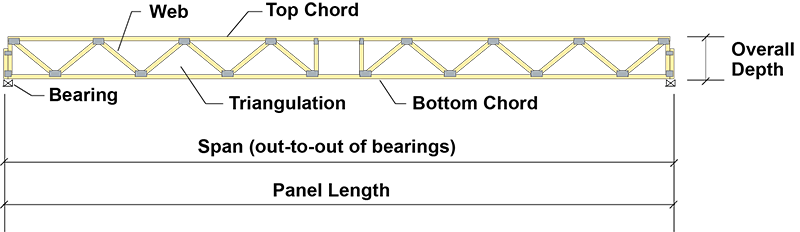

Elements that Make a Floor Truss

- Bearing: Structural support, usually a beam, wall, or post that is designed by the building designer to carry the truss reaction loads to the foundation.

- Bottom Chord: Inclined, or horizontal member that establishes the bottom of a truss, usually carrying combined tension and bending stresses.

- Floor Panel/Deck: A preassembled unit of floor joists, subflooring, finished flooring, and sometimes ceiling below supported by walls, columns, or beams.

- Overall Depth: Vertical distance between bearing and the uppermost point of the peak.

- Panel Length: Horizontal distance between the centerlines of two consecutive panel points along the top or bottom chord.

- Panel Point: Location on a truss where the web members and top or bottom chords intersect and are connected by metal connector plates.

- Span: Horizontal distance between outside edges of exterior bearings.

- Top Chord: Inclined or horizontal member that establishes the top member of a truss.

- Triangulation: The act of forming rigid triangles with objects adequately fastened together.

- Web: Members that join the top and bottom chords to form the triangular patterns typical of trusses. These members typically carry axial forces.